Contents

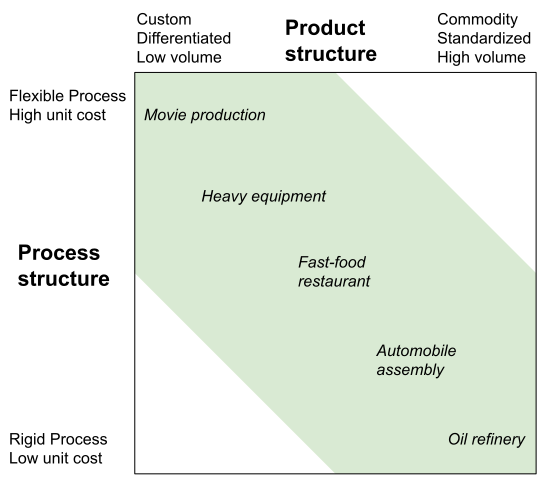

The Hayes-Wheelwright matrix, also known as the product-process matrix, is a tool for analyzing the relationship between the product life-cycle stage and the manufacturing process.

The first dimension of the matrix is the product life cycle, a measure of the maturity of the product or market. It ranges from a highly customized product to a highly standardized product.

The second dimension measures the maturity of the manufacturing process. It ranges from high unit cost to highly automated, low unit cost processes.

Companies can occupy any position in the matrix. According to the framework, they can only be successful if the product life cycle stage is aligned with the process life cycle stage.

In software development, the matrix evaluates your organization based on two criteria: importance and frequency of process usage. It’s a grid where you list all of your company’s processes, then assign them to one of four quadrants depending on how often you use each process and how important it is to your business.

There are many benefits to using the product-process matrix as part of an organizational strategy. You can use the information from this tool to improve efficiency across departments, reduce redundancy, and standardize processes so they’re easier to implement going forward.

Let’s look at what a product-process matrix is and how it can help you as a product manager to develop an effective product strategy.

Expand your knowledge, follow us for more!

What Is a Product-Process Matrix?

The product-process matrix integrates the product life cycle. It also encompasses every stage of the product creation process to create a competitive advantage.

A product-process matrix is a tool for companies to analyze and improve their various processes with organizational competence, through the product life cycle. It provides insight into all of your company’s operations and helps you see how successfully you handle tasks and how often they occur.

Origin of the Product-Process Matrix

In 1979, Robert H. Hayes and Steven C. Wheelwright invented the Hayes-Wheelwright Matrix, which is also known as the Original Product-Process Matrix.

Articles titled “Link Manufacturing Process and Product Life Cycles” and “The Dynamics of Process-Product Life Cycles” were published in the Harvard Business Review and established the concept.

Using the matrix, these two papers looked at challenges in market production processes and came up with strategic solutions. As a result, companies now can make better-informed decisions about the progress of products and associated processes as well as examine the fit.

Why Is Developing a Process Strategy Important in Product Management?

In today’s fast-paced world, people want things done quickly and correctly the first time. Processes should be standardized within an organization to be more cost-effective. Standardizing processes cuts heavy costs and makes for better business opportunities.

Companies that want to be successful need to create processes that can be easily replicated or scaled. Doing so will provide you with a consistent, high-quality product or service. You’ll also have an opportunity to save money in the long run.

Expand your knowledge, follow us for more!

Understanding the Product-Process Matrix

Understanding the product-process matrix gives you strategic marketing options to make informed predictions about the product range and product volumes. The product positioning and consistency with the product will make for continuous flow processes.

Job shop

Companies at the job shop stage often produce a variety of different items at modest production levels. There is a high degree of flexibility because of the low volume of major products. Companies that produce a custom product continuously are considered to be in the lower left corner.

This low volume, customized product (large-scale, one-time, unique products like contracts, construction, and so on) is one of the perks of having amazing products using a job shop process. In a job shop environment, high-volume flow lines are not present because the job shop method focuses more on the individual product. Degrees of customization will depend on the creative thinking of the manufacturing managers.

Batch production

The batch type of production is a step up from a job shop category. The manufacturing volume per good, on the other hand, isn’t great enough to warrant the purchase of specialized equipment with batch operations as project execution performance is still low.

This method of manufacturing is more efficient than a typical job shop since parts are grouped in processes as needed. It’s still at a rather modest volume. The batch process is more efficient because of the recurrence, but it is not a continuous chain of events.

Assembly line

This technique (together with continuous, both in the lower-right quadrant) is called mass production.

Lower-right organizations (line and continuous) have a product layout.

Upper-left quadrant (job shop and batch) and lower-right quadrant share traits (assembly line and continuous).

Lower-right quadrant firms have great volume, scale economies, and low costs. Using an assembly line process, goods with a high degree of similarity are mass-produced repeatedly. There is general-purpose equipment for the production process. As a result, the production process becomes more efficient.

The standardization of the process makes it much easier to control and administer. However, the product has virtually no flexibility or diversity. However, the corporation is now able to create large quantities of things at a faster rate.

Continuous flow

In keeping with the etymology of the phrase, this is a continual process. This necessitates the employment of dedicated equipment. There must be a very narrow range and a very large volume of output to make this efficient and justify the unique equipment.

As a result, when these two characteristics are satisfied, this sort of manufacturing is most efficient since the process is highly standardized. In this instance, it is relatively simple to maintain the same production standards for all items.

The procedure is very rigid, and any changes to the final result are out of the question. There will be a lot of downtime and production pauses if there is any damage to the equipment as well. Repairing the equipment also adds to the overall cost.

Off the diagonal line

Some businesses may decide to use manufacturing techniques and procedures that are not found in the diagonal projects of the matrix, such as the four mentioned above. This is because of cost competitiveness.

There are some corporations where this is bad. This is a result of the cost of production and dangers associated with standing out from the participating rivals.

How to Create a Product-Process Matrix

To create a product-process matrix, you first need to research the process structure your company follows to gain a comparative advantage. That includes every step that goes into producing, managing your supply chain, and delivering products to customers.

For example, let’s say your company manufactures cosmetics. One of your core processes is contacting suppliers for new products to sell. You might also have two other core processes: manufacturing and marketing. These are the three main things that keep your company running on a day-to-day basis. Once you’ve identified these three key processes, it’s time to fill out a matrix with all of the tasks and how often they occur.

You need to list all of these processes in the grid, ideally in a spreadsheet or table.

Finally, you need to assign each process to one of the four quadrants based on the criteria outlined above. As you are doing this, you want to think about what each process brings to the table.

Are they expected? Are they necessary? Are they a waste of time? Are they consistent with your company’s culture? This is important because processes that don’t add value to your business should be either optimized or eliminated.

How to Use a Product-Process Matrix to Develop an Effective Product Strategy

Once you’ve created a product-process matrix, you can use the strategic responses for an effective product development process. Start by using the table to identify areas for improvement. Look for processes that are low importance/low frequency and find ways to improve them.

Then, for high-importance/low-frequency processes, figure out how to increase their frequency and make them a standard part of your business.

Finally, for high-importance/high-frequency processes, find ways to optimize these and ensure they remain consistent and standardized across your organization.

Once you’ve identified areas for improvement, you need to prioritize them so you know which processes to work on first. Using the table, determine which processes are the most frequently used. This will help you identify which processes to optimize first.

Expand your knowledge, follow us for more!

Determining Which Processes Are Important and Which Are Not

When it comes to process mapping, the first step is determining which processes are important and which are not. You will want to choose what is most important for your company, as well as what processes are just “nice-to-haves.” This could change over time, but it’s good to start with a list of tasks that you think should be on your matrix. Tasks can include anything from creating marketing materials, managing customer feedback, and manufacturing your product.

Which Processes Are the Most Frequently Used?

When evaluating the product-process matrix, you also want to look at which processes are the most frequently used. This is important because it gives you an idea of where improvements can have the biggest impact. By focusing on the most frequently used processes, you can improve the efficiency of your organization in a way that directly affects customers.

You can also have the largest impact on the bottom line.

Depending on what you find when you evaluate the product-process matrix, you may also want to reprioritize certain processes. For example, if inventory management or purchasing processes are the most frequently used, you may want to prioritize improving them if they are currently of high importance/high frequency.

Which Processes Should Be Reprioritized?

Once you’ve identified which processes need to be improved, you might need to figure out which one is most important, if there are several.

Again, you want to use the product-process matrix to determine which processes are the most important. You then want to prioritize reprioritizing those that are high importance/low frequency.

Processes that are high importance/low frequency are valuable but they are not being used as often as they should be. By reprioritizing these processes, you can optimize your organization and increase efficiency.

For example, your company may have an amazing CRM system but not enough staff to use it properly. The CRM process is high importance/low frequency, so by reprioritizing it, you can increase its frequency and make it an even more useful tool for your organization.

Finding Areas for Improvement

A product-process matrix is a great way to find areas for improvement. If you find that certain tasks are taking up too much time while others don’t happen frequently enough, then it might be a sign that something needs to change.

For example, you might find that regularly your employees need to do data entry tasks. This discovery would lead you to think about whether incorporating more automation into the disconnected line flow would help make for a smoother flow.

You can also use a matrix to see how often certain tasks are completed and if there are any inefficiencies in the system.

Organizational Strategies Based on the Results of Your Product-Process Matrix

A product-process matrix can help you get a better handle on your company’s operations. It can also help you identify the most effective processes and those that aren’t going well. For example, you may find that some of your processes are more effective than others. You may also find that some processes make sense when they occur once or twice, but not when they happen five times or more.

If this is the case with any of your processes, then it might be time to consider reorganizing them. It makes sense to do this if there are any inefficiencies in how often tasks happen or if they’re happening too often, among other things.

For instance, if one of your tasks, like customer service queries, is happening too often (i.e., 15 times a day), then it might make more sense to hire an assistant to take over this task for you so you have more time for other areas of the business.

Summing Up

Product-process matrices map the value stream to identify representative items, services, or information.

Using the matrix, combine sensory elements from new and previous clients by mapping particular tangibles onto these processes.

Connect with what your consumers love and allow it to develop into the product. You’ll design a better product for end-users.